In any given asset-intensive operation, the type of spare parts, their availability, categorization, management and synchronization with other key datasets are critical not only to ensure that production facilities run seamlessly without any disruption but also to ensure that the entire operation is efficient with minimal overheads and and wastage.

As production operations scale, the need for a systematic process becomes glaringly apparent and it becomes important to centralize operations and have some sort of a software-led approach to introduce automations, historic context, data and analysis and a robust audit-trail of activities.

Enterprises that are in upstream & midstream energy operations, Mining & Metal Extraction and Manufacturing would find this information particularly relevant.

As per a report by Siemens,

Every unproductive hour now costs automotive manufacturers a staggering $2.3 million.

There are a few aspects that help build a holistic management strategy for spare parts.

Segmentation of Spare Parts Based on Usage

Identifying Critical Spare Parts

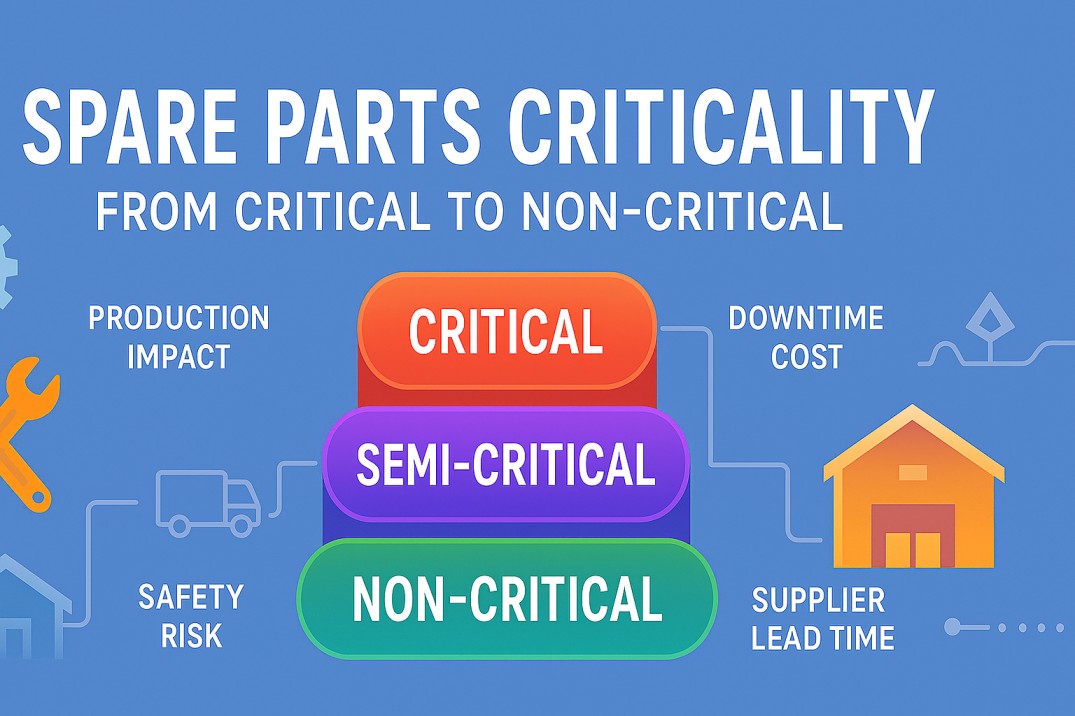

Identification of the criticality of a spare part or a consumable is a foundational aspect in Enterprise Asset Management, MRO Inventory Management and Effective Data Management Practices.

The criticality of spare parts could mean that a spare part might be rarely used, yet if its not available at the time of requirement, it could lead to a halt in the production or even an equipment or machine breakdown.

Similarly there are some spare parts, that can be interchangeably used in different machines, therefore, avoiding the plant downtime, and some spare parts that are storage sensitive, and might breakdown in certain weather conditions.

Identifying and segmenting the spare parts could help the maintenance department from avoiding equipment and plant shutdowns, production losses, predicting the parts that should be stocked more and needs high maintenance.

While this differs from company to company, a standard scoring matrix is based on multiple dimensions, that generally includes an assessment on the following pointers.

Does the failure of the part lead to complete equipment shutdown or reduced functionality?

Is it part of a production bottleneck or high-utilization asset?

Are there redundant systems or backups in place?

Sometimes a part might still be functional, but it might lead to slower output or low quality, thus impacting the operations.

Its important to understand the complete operational chain and prioritize the spare parts correctly.

Safety and Environmental Risk

- Could failure cause safety hazards to personnel or the environment?

- Is the part part of a compliance-critical system (e.g., fire suppression, emission control)?

Some parts are used in an equipment to mitigate the safety and environmental risk of operations, and the criticality of such parts is always high, since the failure or unavailability of such spare part can cause huge damages.

Regulatory non-compliance and safety incidents can incur fines, lawsuits, or license suspensions. A spare that prevents such events must be treated as critical.

Cost of Downtime

- What is the financial impact per hour/day of equipment downtime due to this part?

- Is the part related to revenue-generating operations?

Even one hour of downtime can translate into tens or hundreds of thousands of dollars in losses. A report by Mining Weekly stated that “downtime of a mining dump truck can cost up to ~USD$1 000 per hour, and an excavator costs even more”

- Is the part readily available or does it have a long procurement lead time?

- Is it a custom part, OEM-protected, or obsolete?

- Can it be procured locally or must it come from overseas?

If a part’s procurement involves uncertainty, complexity, or extended timelines, it quickly shifts from a routine item to a strategic risk. Parts tied to specific OEMs, manufactured overseas, or no longer in active production can’t be sourced on short notice.

- How often does this part fail or require replacement?

- Is it on a preventive maintenance plan?

This criterion looks at how frequently a spare part is expected to be used, replaced, or fail in practice. Parts with a high failure rate, or those that are regularly replaced during preventive maintenance cycles, must be available in adequate quantities to support routine upkeep.

Usage frequency can be determined from maintenance logs, or patterns observed over time. A fast-wearing component can cause recurring inefficiencies if it’s not stocked properly. Therefore, high-frequency parts, even if cheap or simple, often rank higher in stocking priority.

Ascertaining parts criticality alongside equipment criticality informs EAM and procurement teams on the right stocking levels to be maintained for disruption-free production operations.

Identifying Slow Moving Parts

In a study done by McKinsey back in 2019 but still very relevant today, it is estimated that anywhere between 10 to 40% of the overall MRO spare parts are slow moving and are rarely used. This number is generally much higher for companies in Oil & Gas, Mining Operations, Transmission etc.

Understanding slow moving parts is of key importance, unfortunately, procurement and asset management teams are generally not adequately informed of which spares are slow-moving and this tends to inflate overhead costs needlessly.

Companies generally maintain a threshold of 12-months and rely on their historical inventory movements to ascertain whether a spare part is slow moving.

In our Experience At Verdantis, we have also observed similar statistics as far as slow-moving parts are concerned. This can directly inflate ….

Needlessly stocking huge numbers of spare parts is a wastage and has a direct bearing on the efficiency of the MRO inventory management processes.

Fast Moving Parts

Conversely, identifying fast moving spare parts is also of importance for effective sourcing strategies, and to ensure that inventory levels of spares that are used frequently are maintained adequately, with buffer.

And this brings us to the next point.

Insurance Spares

Insurance spares are not your everyday spare parts. These are critical components that companies keep in stock not for frequent use, but as a strategic safety net.

They are typically expensive, rarely used, and difficult to replace quickly. Think of them as a form of “operational insurance.”

These parts don’t show up in your regular preventive maintenance cycles, and in most cases, they may never be used at all.

But if a failure does occur – especially in a key piece of equipment – the presence of these spares can mean the difference between a quick recovery and weeks of costly downtime.

In capital-intensive industries, downtime isn’t just an inconvenience – it’s a financial risk. Whether it’s a mining conveyor, a power turbine, or a production line motor, a breakdown without a spare can cost millions per day in lost productivity and penalties. Insurance spares are a proactive shield against such disruption.

Many of these components are custom-engineered or sourced from specialized OEMs, with lead times stretching from 6 to 18 months. For legacy equipment, delays can be even longer due to discontinued parts or special fabrication needs.

What happens when your equipment vendor stops supporting your model? This is a very real issue. Insurance spares hedge against obsolescence and supply chain vulnerabilities by ensuring parts are available even when the market dries up.

In sectors like oil & gas, energy, and pharmaceuticals, having immediate access to specific spares is more than smart – it’s a legal or safety requirement. Regulatory standards often mandate that critical systems be restored without delay, especially when safety or environmental controls are involved.

Obsolete Spares

Depending on the nature of business, industry and scale of operation, almost 15% of the overall MRO stock parts can be obsolete.

Unlike other categories here; obsolete spares result in losses since they directly inflate holding costs and if they are also a critical spare, they can cause further damage due by way of unplanned downtime.

Rotable Spares

Rotable spares (or “rotables”) are high-value, repairable spare parts that can be rotated through a cycle of use, repair, and reuse.

Unlike consumables (which are used once and discarded), rotable spares are refurbished or overhauled after failure or wear, then returned to inventory for future reuse.

- Lower Inventory Costs: Since rotables are reused, fewer spares are needed overall compared to stocking many non-repairable items.

- Higher Tracking Requirements: Each rotable must be tracked individually for its condition, repair history, and service limits.

- Turnaround Time Management: Fast repair cycles are critical to ensure availability and avoid stockouts.

Categorization of Spare Parts

While segmenting the spare parts based on usage patterns, obsolescence status and their role in the maintenance process is important for an overarching maintenance strategy, the categorization of spares based on their intrinsic properties, form, fit and function are important for effective warehousing and deployment for any given upkeep operation

Moreover, categorizing MRO spares effectively as per a central standard is also critical to build excellence in data management that we will discuss in the next section.

Spare Parts Data Management

Data quality concerns with respect to their spare parts is one of the leading issues that plague manufacturing heavy firms.

Due to poor data stewardship, a total absence of centralized planning and a non-existent data governance system for Master Data, MRO datasets are a total mess.

Correcting this requires a service + software-enabled data management solution for MRO spare parts.

MRO Data Normalization

Also referred to as cleansing of MRO spare parts, this entails gathering all legacy MRO parts data that have been in-use and ensuring that the dataset is free from inconsistencies like duplicates, missing information, conflicting data points and miscategorized spare parts.

At this stage, depending on the extent of “missing information” and “conflicting data points”, a company may choose to enrich the dataset through several methods like deploying purpose-built software or employing subject matter experts to fetch and update this information

The video below can detail how MRO data Enrichment works in-line with ….

MRO Governance

But cleansing and enrichment alone are not enough. To ensure that the spare parts data remains clean, accurate, and usable over time, organizations need to implement a structured system of MRO Governance.

MRO governance lays out policies that define how spare parts data is created, maintained, and controlled throughout its lifecycle. At its core, it brings discipline and consistency to an otherwise fragmented and ad hoc process.

The spare parts data is standardized using naming conventions, classification schemes (such as UNSPSC or eCl@ss), and attribute requirements that every spare part record must adhere to. This ensures that regardless of who creates or modifies a part record, it follows a consistent structure that makes it easy to search, procure, and manage.

Governance also introduces control mechanisms that prevent poor-quality data from entering the system in the first place. Approval workflows ensure that new material requests go through a validation process – checking for duplicates, confirming critical attributes, and aligning with inventory and maintenance requirements – before being accepted into the master.

Every part record is tied to an audit trail, which records who made what change and when, thereby improving accountability and traceability.

MRO governance lays the foundation for scaling automation and AI-based data management tools. Whether it’s automating classification or enriching missing attributes using AI, these tools rely heavily on a well-governed data model, improving the accuracy.

Without this structure, even the most advanced technologies can fall short or produce inconsistent results.

At Verdantis, we’ve built intelligent AI agents specifically designed to work within these governed frameworks that ensure consistency, traceability, and speed in spare parts data management.

Here is the video explaining how Verdantis’ Auto Enrich AI helps in enriching and mapping the spare parts data, and tracking the obsolete.

Prudent spare parts management has dual objectives. For one, it must be ensured that instances of unplanned downtime are kept to a minimum.

Secondly, overheads linked to overstocking, last minute maverick spending etc are kept to a minimum.

To build effectiveness in the same, it is critical to understand not just critical spare parts but also critical pieces of equipment and ensuring that these are linked effectively with the right software.

For proprer equipment data maintenance, it is required to map each spare part to its relevant equipment, asset, or system. This enables maintenance teams to view spare parts in the context of where and how they are used, making it easier to plan maintenance activities, identify replacements, and analyze failure trends.

A synchronized view also helps identify underused or misallocated parts and ensures that maintenance BOMs (Bill of Materials) are accurate and up to date. This alignment reduces ambiguity, facilitates preventive and predictive maintenance, and helps streamline work order execution.

Real-time integration with inventory management systems ensures that spare parts data reflects actual stock levels, movement history, reorder points, and lead times. This integration prevents stockouts, reduces duplicate material creation, and enhances procurement accuracy.

It also enables dynamic inventory optimization – helping planners adjust stocking strategies based on current demand, seasonal trends, and asset utilization. Such synchronization is key to supporting just-in-time maintenance models and improving inventory turnover ratios.

MRO Obsolesence Management

As asset-intensive industries evolve and equipment lifecycles extend, managing obsolete spare parts has become a critical element of an effective MRO strategy. Obsolescence refers to spare parts that are no longer in production, supported by the OEM, or compatible with updated systems and assets.

These components may still exist in the inventory but are unusable – leading to wasted storage space, inflated carrying costs, and procurement challenges during emergency repairs.

Proactive MRO parts obsolescence management involves regularly identifying, classifying, and eliminating non-moving and end-of-life parts from the inventory.

This begins with establishing a clear obsolescence tracking mechanism that flags parts based on factors such as last movement date, OEM discontinuation notices, or lack of usage over a defined period (commonly 12 to 18 months).

In addition to inventory audits, maintenance BOMs and asset hierarchies must also be reviewed for obsolete parts to prevent their continued planning or procurement.

Integrating obsolescence intelligence into ERP and CMMS systems helps trigger alerts when maintenance teams attempt to use or request outdated parts, prompting alternatives or engineering evaluations.

And here are 2 videos explaining how Verdantis’ BOM and spare parts management helps organizations in maintaining their equipment and asset data.

AutoDoc AI

SpareSeek AI

Where critical parts are at risk of obsolescence, organizations must consider:

Last-time buys to stock up before production ends,

Reverse engineering or local fabrication as a fallback,

Vendor diversification to avoid single-source dependencies,

And collaborative planning with engineering and procurement teams to identify interchangeable substitutes.

Effective obsolescence management not only reduces dead stock and improves inventory health but also strengthens supply chain resilience and ensures uninterrupted maintenance and production continuity.

By incorporating it as a continuous process – rather than a one-off clean-up – organizations can transform obsolescence from a hidden risk into a well-governed function that directly supports operational excellence.

There are different obsolesences in MRO like:

Technical Obsolescence

When a component or system becomes outdated due to technological advancements, or even if the part is still operational, it may no longer align with modern systems or current engineering practices is when a part becomes technically obsolete.

Logistical or Supply Chain Obsolescence

Some parts become obsolete not because of performance or cost issues, but due to supply chain challenges. Discontinuation by the manufacturer, lack of vendor support, or disruptions in global sourcing can render parts effectively unusable.

Regulatory Obsolescence

Changes in safety, environmental, or industry regulations can lead to obsolescence if parts fail to comply with updated standards. Organizations may be required to replace or phase out non-compliant components to maintain certifications or avoid penalties

Effective spare parts management is no longer a support function – it is a strategic enabler of operational efficiency, asset reliability, and bottom-line performance. As industries move toward more digitized and connected operations, spare parts data and processes must evolve accordingly.

By combining intelligent segmentation, detailed categorization, rigorous governance, and synchronized sourcing strategies, companies can dramatically reduce downtime, cut inventory costs, and improve overall maintenance responsiveness.

Organizations that take a proactive approach to spare parts management today will not only reap immediate gains in efficiency but also build a foundation for more advanced practices like AI-led forecasting, autonomous MRO planning, and digital twin-enabled maintenance in the future.

With the right blend of strategy, technology, and data governance, spare parts management becomes a powerful lever to drive excellence in maintenance operations across asset-intensive industries.

Can interchangeable parts reduce the number of critical spares needed?

Yes. When parts can be used across multiple assets or have known substitutes, it reduces the need to stock multiple unique items. Interchangeability adds flexibility in inventory and procurement, improves availability, and can lower overall spare parts inventory costs without compromising uptime.

How can organizations manage interchangeable, equivalent, or alternative spare parts efficiently?

By enriching part records with:

OEM/alternate manufacturer info

Technical attribute comparison

Approved equivalency lists

Cross-referenced substitutions in ERP (e.g., SAP Material Master: Alt Parts)

This supports sourcing flexibility, reduced lead time, and inventory rationalization.

How can spare parts data management directly influence asset uptime and maintenance efficiency?

Spare parts data directly impacts maintenance planning and work execution. Inaccurate or missing part data in equipment BOMs can lead to incorrect parts being issued, last-minute procurement, or extended downtime. Well-managed data ensures technicians receive the right part the first time – minimizing MTTR (Mean Time to Repair) and unplanned downtime.

What is the difference between internal part numbers and manufacturer part numbers?

Internal part number (IPN): The unique ID used within an organization’s ERP or inventory system.

Manufacturer part number (MPN): The identifier assigned by the OEM or supplier.

Maintaining both is essential for traceability, sourcing, and avoiding duplication.

What policies should an MRO data governance framework include?

Clear ownership for spare parts data is critical – identifying who can create, approve, and modify records. It should include standardized naming conventions, classification rules, and attribute requirements to ensure consistency across systems.

Policies must also address duplicate prevention, approval workflows for new material requests, data quality metrics, and audit trails to maintain traceability. These controls help maintain clean, searchable, and reliable data across the asset lifecycle.

What criteria are used to determine whether a spare part is critical?

Criticality is typically based on multiple factors: the operational impact of failure, safety or environmental risks, cost of downtime, lead time for procurement, and frequency of use. A part may be rarely used but still critical if its absence can halt a key asset.

Conversely, frequently used parts may not be critical if they’re easy to source quickly and don’t cause major disruption when missing.