Procurement today is no longer just a support function, it plays a critical role in driving business value, managing risk, and supporting sustainability goals.

Central to this evolution is the quality and governance of procurement master data. By integrating procurement master data management (MDM) with strategic sourcing and operational processes, organizations can unlock measurable benefits in efficiency, cost savings, and compliance.

Understanding Procurement Master Data

Procurement Master Data Management refers to the structured process of organizing, standardizing, and maintaining critical data related to suppliers, materials, and services. This data underpins all sourcing and purchasing activities and is essential for driving efficiency, reducing risk, and enabling informed decisions.

Clean and consistent procurement data especially for materials and services like MRO is vital in asset-intensive industries such as manufacturing, energy, oil & gas, and mining, where it directly impacts asset reliability, inventory costs, and operational uptime.

As organizations expand across geographies and systems, procurement data becomes fragmented, leading to inefficiencies, redundant records, non-compliance, and poor supplier performance. A unified MDM framework addresses these challenges by:

Centralizing and standardizing supplier and item data

Creating a single source of truth across ERP, CMMS, and procurement platforms

Supporting efficient sourcing, supplier collaboration, inventory optimization, and compliance

Though procurement master data isn’t a standalone ERP module, it supports all procurement operations, from purchasing execution to vendor data management by ensuring consistent and trustworthy data across the enterprise.

A 2025 Gartner report found that 49% of procurement leaders cite data accuracy and reliability as a significant challenge, despite 68% of CPOs investing in AI and generative tech, indicating a critical gap in data maturity and analytics readiness.

Find the Right Parts, Suppliers, and Insights

Types of Procurement Master Data

Effective procurement hinges on the accurate and well-maintained management of various master data types. These foundational data domains serve as the bedrock for all purchasing activities, from initial requisition to final payment.

A robust master data framework ensures consistency, compliance, and efficiency across the entire procure-to-pay cycle. The key categories of procurement master data and their typical attributes include:

1. Material Master Data

Control important settings like:

Procurement type (internal, external, or both)

Inventory valuation method (standard price or moving average)

Required data views during material master creation

For MRO, the material master data becomes exceptionally detailed and critical, as it often involves spare parts, consumables, tools, and safety equipment. This domain provides a comprehensive description of each tangible item procured, stored, and used.

Key Attributes & Data Included:

1. Core Identification

Key Attributes & Examples

- Part Number/SKU: e.g., INT-0002345, SKF-6205-2RS

- Description: e.g., Bearing, Ball, Double Row, Sealed, SKF

- Commodity Code: e.g., UNSPSC 31171504 (Ball Bearings)

- OEM & Cross-Ref Numbers: e.g., ABB-435634 / Siemens-ABX12

- Manufacturer: e.g., SKF, ABB, Siemens

- Drawing No.: e.g., DWG-334/Rev B

2. Technical Specifications

Key Attributes & Examples

- Specs: e.g., ID: 25mm, OD: 52mm, Width: 15mm

- UOM: EA, KG, L, M

- SDS Link: Required for lubricants, chemicals

- Hazard Flags: e.g., Flammable, Toxic

- Shelf Life: e.g., 24 months (sealant)

- Warranty: e.g., 12 months from install date

3. Inventory & Planning

Key Attributes & Examples

- Location: e.g., Warehouse A, Bin 03-C4

- Conditions: e.g., Store below 25°C

- Reorder Point: 10 units

- Min/Max Stock: 5/50 units

- Lead Time: 14 days

- Usage Rate: Monthly avg: 20 pcs

- Criticality: e.g., A – Downtime risk

- Obsolete Flag: e.g., Yes – Replace with PN 123456

4. Costing & Valuation

Key Attributes & Examples

- Valuation Class: 3000 – Raw Material

- Standard Price: $45.20/unit

- Last Purchase Price: $47.00 from Supplier X

2. Service Master Data

Defines intangible services. Less emphasis on physical attributes, more on descriptive and contractual terms. Service master data defines procured services (like maintenance, consulting, IT support) within ERP/procurement systems. It includes descriptions, categories, pricing, suppliers, and contract terms.

Why It’s Important

- Provides a unified, accurate view of all procurement—goods and services

- Enables spend analysis, cost control, and compliance

- Supports better supplier selection and risk management

- Requires collaboration across departments (IT, HR, Facilities) to stay current

- Strong service data helps negotiate better contracts and align with business needs

Key Attributes & Data Included:

1. Service Definition

Key Attributes & Examples

- Service Number : Unique ID, e.g., SERV-00123

- Service Description : “Preventive Maintenance for Pump P-101”, “HVAC System Inspection”

- Service Category : “Electrical Services”, “Cleaning Services”, “Calibration”

- Service Type : “On-site”, “Fixed Price”, “Time & Material”, “Remote”

- Unit of Measure : “HR” (Hours), “DAY”, “TRIP”, “EA” (Each), “KM”

- Skill Requirements / Certifications : “Certified Electrician”, “Level 2 HVAC Technician”

2. Pricing & Contracts

Key Attributes & Examples

- Default Rate/Price : “$150/HR”, “$500 per trip”

- Price Currency : “USD”, “EUR”, etc.

- Price Validity Period : “01-Jan-2025 to 31-Dec-2025”

- Overtime Rates : “$200/HR after 6 PM”

- Travel Charges : “$0.75 per KM”, “Flat $100 per site visit”

- Service Level Agreements (SLAs) : “Response in 4 hrs”, “Resolution within 24 hrs”

- Warranty on Service : “30-day workmanship warranty”

3. Operational Linkages

Key Attributes & Examples

- Associated Equipment / Asset : “Applicable to Boiler B-302”, “Only for CNC Lathe Machine”

- Safety Requirements : “Confined Space Entry”, “Lockout/Tagout required”

- Regulatory Compliance : “Complies with OSHA 1910”, “ISO 17020 Certified Inspection Required”

3. Supplier/Vendor Master Data

This domain consolidates all critical information related to an organization’s external partners. It’s often structured with core data, address data, banking data, and purchasing organization-specific data.

Key Attributes & Data Included:

1. MRO Specialization / Capabilities

Key Attributes & Examples

- MRO Vendor Type : “OEM Distributor”, “Aftermarket Parts Supplier”, “Specialized Service Provider”

- Product/Service Categories Supplied : “Bearings”, “Electrical Supplies”, “Pumps & Valves”, “Hydraulic Repair Services”

- Technical Support Availability : “24/7 Hotline”, “Dedicated Tech Rep for Tier 1 accounts”

- Repair & Calibration Services : “Pump repair”, “ISO 17025 Certified Calibration for Pressure Gauges”

- Local Stock/Warehouse Presence : “Warehouse in Mumbai”, “Regional hub in Houston for fast delivery”

- Minimum Order Value / Quantity : “No minimum”, “$100/order minimum”, “MOQ of 5 units for certain parts”

2. Performance & Relationship Data

Key Attributes & Examples

- Emergency Service Capability : “Emergency delivery within 4 hours”, “Weekend support available”

- Supplier Rating for MRO: “Rated 4.8/5 for lead time adherence”, “95% on-time delivery for critical spares”

- Returns Process Efficiency : “RMA processed in 3 days”, “Self-service return portal for incorrect parts”

4. Purchasing Info Records (PIRs)

PIRs for MRO items are critical for standardizing procurement of frequently ordered parts from specific suppliers and maintaining competitive pricing.

Key Attributes & Data Included (MRO emphasis):

- Material/Service Number & Vendor Number Linkage

- Order Unit (often different from base UOM for bulk MRO purchases)

- Net Price and Price Unit (e.g., “USD 10.00 / 100 PC”)

- Planned Delivery Time (very important for critical spares)

- Minimum Order Quantity / Packaging Size

- Supplier Material Number (the supplier’s own internal part number for cross-referencing)

- Last Purchase Date & Last Price Paid

- Invoice Verification Tolerance Limits (due to high volume, low value often means wider tolerances)

5. Contracts & Pricing Agreements

MRO contracts often take the form of blanket purchase agreements or master service agreements to cover recurring needs and leverage spend.

Key Attributes & Data Included:

- Contract Type (e.g., Blanket Purchase Order for general consumables, Service Level Agreement for maintenance contracts)

- Target Value/Quantity (can be for a category of MRO items or total spend with a supplier)

- Validity Periods

- Specific Pricing Schedules (e.g., tiered pricing based on annual volume, fixed rates for specific maintenance tasks)

- Rebate Agreements (common for MRO to incentivize consolidation of spend)

- Service Level Terms (e.g., guaranteed uptime for equipment, maximum response times for breakdowns)

- Geographic Coverage (for service contracts, which regions/plants are covered)

- Call-out Fees/Minimum Charges for service visits

- Penalty Clauses for non-compliance with SLAs.

6. Asset Master Data

While not strictly “procurement” master data, Asset Master Data is fundamentally intertwined with MRO procurement. It defines the equipment and facilities that require maintenance and, therefore, MRO parts and services.

Key Attributes & Data Included:

- Asset ID (Unique Identifier)

- Asset Description (e.g., “CNC Milling Machine – Haas VF-2”)

- Asset Type/Category (e.g., “Pump,” “Motor,” “Vehicle,” “HVAC Unit”)

- Location (Plant, Department, Work Center)

- Manufacturer, Model, Serial Number

- Installation Date, Commissioning Date

- Warranty End Date

- Criticality Rating (Impact on production if this asset fails)

- Associated MRO Parts List/Bill of Materials (BOM) (critical for linking assets to the specific spare parts they consume)

- Maintenance Plans (Preventive, Predictive) and Maintenance Frequencies

- Last Maintenance Date, Next Due Date

- Service History (links to service orders and associated MRO parts used)

The effective management of these MRO-specific master data types is crucial for minimizing downtime, optimizing inventory levels (avoiding both stockouts and overstocking of often expensive spares), streamlining the purchasing process for a high volume of small transactions, and gaining better control over MRO spend. It’s often the lack of clean, standardized MRO master data that leads to significant inefficiencies and hidden costs in large organizations.

According to the IBM Institute for Business Value (June 2025), early adopters of AI-driven procurement innovation expect a 12% improvement in ROI, 20% boost in productivity, 14% increase in operational efficiency, and 11% rise in profitability. By 2027, they also anticipate 41% better sourcing efficiency, 49% more touchless invoice processing, 36% higher compliance, and 43% improved real-time spend visibility.

Who Uses Procurement Master Data

Procurement data supports decision-making across functions:

Industries That Rely Heavily on Procurement Master Data

Where Procurement Data is Used

Procurement master data is integrated into:

- ERP systems (SAP, Oracle, Microsoft Dynamics)

- eProcurement tools (Coupa, Ariba)

- Supplier portals and Contract Lifecycle Management (CLM) tools

- CMMS/EAM systems (Maximo, Infor, SAP PM)

- Analytics dashboards for spend, compliance, and supplier performance

Procurement Management Process Overview

Procurement functions typically follow two major workflows:

- Procure-to-Pay (P2P): Covers everything from requisition to supplier payment.

- Source-to-Contract (S2C): Involves supplier discovery, RFPs, evaluation, and contract finalization.

Each step depends on reliable master data. Even small errors,like a duplicate vendor or incorrect unit of measure,can delay purchasing or trigger financial risks.

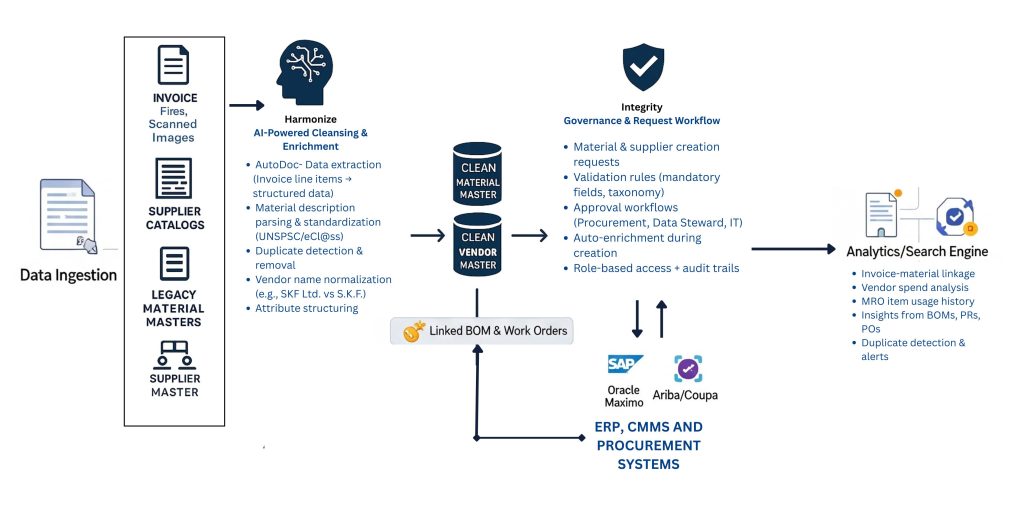

Procurement master data management starts with extracting data from invoices, POs, and catalogs. Verdantis Harmonize cleanses, standardizes, and enriches material and vendor data, linking it to BOMs, work orders, and supplier records. Through Integrity, users can request new materials or vendors via controlled workflows.

The finalized data integrates into ERP systems, enabling accurate procurement, better spend visibility, and fast, searchable access to trusted information.

The entire process, from data scraping to part ordering, can be automated, allowing users to cross-check inventory, supplier, and pricing data instantly using a single command on the analytics-driven procurement dashboard.

Step-by-Step Procurement Master Data Management Process

Procurement Master Data Management ensures structured, complete, and standardized service and supplier records across your enterprise systems – covering everything from vendor profiles to service definitions, pricing, compliance, and transactional data.

Objective: Extract raw procurement data from siloed platforms and documents into a centralized master dataset.

How it works:

Verdantis AutoDoc AI, intelligent document processing agent, ingests structured and unstructured procurement data from:

ERP systems (SAP, Oracle, Microsoft Dynamics)

eProcurement tools (Ariba, Coupa)

Contracts, RFQs, SLAs, invoices (PDF, Excel, scanned docs)

Vendor databases, catalogs, and spreadsheets

AutoDoc AI parses and identifies:

Supplier profiles, service descriptions

Pricing terms, service categories

Contract metadata (e.g., start/end dates, T&Cs)

Outcome: A unified, structured dataset ready for profiling, classification, and standardization.

Objective: Classify vendors and services into standardized procurement categories for analysis and control.

How it works:

Verdantis AutoClass AI:

Translates multilingual descriptions using AutoTrans AI

Categorizes records into taxonomies like:

Identifies high-level service groupings (e.g., “Electrical Maintenance” → “Facilities Services”)

Outcome: Structured classification that supports spend analysis, sourcing strategy, and compliance alignment.

Objective: Define attribute sets for each service category or supplier type.

How it works:

Templates include required fields such as:

For services: Service number, UOM, SLA, pricing, certifications

For vendors: Supplier type, compliance docs, emergency capability, rating

Attributes are mapped to defined service classes, e.g.:

“Preventive Maintenance for Pumps” → [Service Category: Mechanical Maintenance, UOM: HR, SLA: 48 hrs]

Outcome: Structured templates ensure uniform and complete service/vendor records.

Objective: Extract and assign detailed information from legacy descriptions and documents.

How it works:

AutoSpec AI,

- AutoSpec AI, attribute extraction and data mapping agent for MRO data extracts data like:

“USD 150/hour, 24/7 service, confined space permit required” →

Rate: 150 USD/HR

Availability: 24/7

Safety: Confined Space Entry

Pulls metadata from:

SLAs, contracts, invoices

Vendor onboarding forms

Outcome: Procurement records become structured, searchable, and comparable.

Objective: Standardize fields across systems and geographies.

How it works:

UOM normalization: “HR”, “Hours”, “hr” → “HR”

Currency standardization: ₹, INR → “INR”

Text formatting: “Certified welder Level-2” → “Certified Welder, Level 2”

Outcome: Consistent and clean data that supports analytics and integration.

Objective: Enhance service/vendor records with missing fields and contextual intelligence.

How it works:

AutoEnrich AI for automated attribute extraction and mapping uses:

OEM/vendor websites, catalogs, compliance portals (e.g., ISO, OSHA)

Previously cleansed internal records

Industry benchmarks (rate cards, SLA norms)

Examples:

Vendor record missing safety certifications → auto-filled from portal

SLA response time inferred based on vendor type and past performance

Outcome: Richer, more informative records that reduce sourcing risk and speed up decision-making.

Objective: Flag outdated suppliers, expired contracts, or non-compliant service records.

How it works:

SpareSeek AI flags obsolete parts and identifies:

Expired licenses or insurance

Non-renewed contracts or inactive vendors

Duplicated vendor codes across business units

Outcome: Risk-prone or irrelevant records are flagged, deactivated, or archived.

Objective: Eliminate duplicates across supplier and service records.

How it works:

Level 1: Fuzzy and token matching → “ABC Tech Ltd.” vs. “A.B.C. Technologies”

Level 2: Semantic clustering using AutoClass AI

De-duplication logic uses:

PAN/VAT numbers

Contact/email fields

Service definitions

Outcome: One vendor = one clean record across the enterprise.

Objective: Push cleansed procurement master data into ERP, procurement, and analytics systems.

How it works:

Output formats aligned with SAP MM, Ariba, Oracle Fusion, Coupa, etc.

Data is validated and uploaded via Verdantis Integrity

Localized naming (via AutoTrans AI) where required

Outcome: Clean, governed, enterprise-wide procurement master data, ready to support sourcing, payments, compliance, and strategic decisions.

Objective: Maintain long-term procurement data quality, compliance, and control.

How it works:

Assign data stewards and define clear ownership for service, material, and vendor records

Establish automated workflows for change requests and approvals (via Verdantis Integrity)

Implement regular audits, exception reporting, and automated quality checks

Ensure governance policies are enforced through business rules and role-based access

Outcome: A sustainable governance framework that ensures procurement master data remains clean, consistent, compliant, and audit-ready across the enterprise.

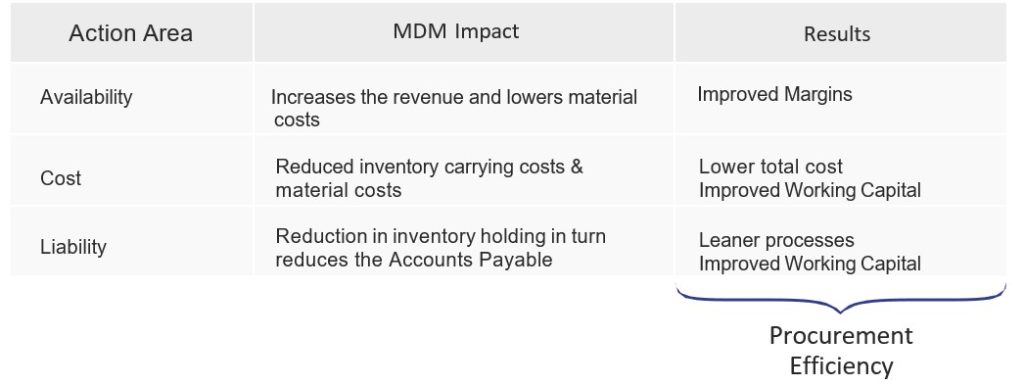

MDM's Impact on Procurement

MDM provides value to procurement in the following three key areas

> Availability > Cost > Liability >

Case 1:

Value addition by ensuring availability:

Organizations generally face the problem of availability of spare parts or for that matter raw material. The real issue though is not one of availability but visibility. Several times the material present are classified under different item names and descriptions creating an almost artificial lack of availability.

Case 2:

Value addition by managing cost:

Organizations procuring at a global level come across same products with different item nomenclature and descriptions. This can also happen with the different parts of machinery. It may so happen that the procurement department purchases the same component at different prices from suppliers.

MDM helps in consolidating these discrepancies by having a uniform definition of materials across the organization. This helps the procurement department to reduce cost associated with the carrying of inventory. The consolidation of components also has a direct impact on the inventory holding cost by ensuring optimum inventory levels.

Example: Average overall inventory costs accounted for 6.3% of an organization’s annual sales revenue. For a hypothetical organization with $150 million per year in revenue, a 15% reduction in inventory carrying costs translates to an annual savings of more than $1.4 million

MDM plays a crucial role in reducing the inventory levels as discussed before thus, having a direct impact on the profitability of the company.

Case 3:

Value addition by managing liability:

Liability in an organization arises basically from accounts payable.

With no common nomenclature present, inventory levels increase invariably resulting in increased accounts payable. MDM ensures optimized inventory levels which ensure decreased liability.

Let us look into how MDM impacts these procurement areas,

Procurement & MRO Master Data

Master Data Management for MRO parts is a critical piece that procurement teams rely on.

MRO refers to “Maintenance, Repairs & Operations” and data management plays a key role in ensuring the right part is made available at the right time to keep manufacturing and equipment maintenance processes up to date.

Any mismanagement of MRO data directly affects procurement decisions, potentially increasing inventory carrying costs OR resulting in production downtime, all of which can be directly linked to mismanaged procurement decisions.

Why the relationship matters?

Take an example where spare part A sold by Supplier ABC already exists in the MRO master data and is linked to equipment X as a critical spare part that must be made available at all times;

During the course of operations, the same spare part sold by another supplier XYZ, also finds its way into the system; due to poor data governance practices that simply cannot weed out duplicate parts based on the attributes, units of measure and features, this identical spare part is also created as an entry, and will consequently be procured, thus increasing the inventory size unnecessarily, inflating operating costs further.

Foundational Procurement Data for Strategic Operations

Vendor information, onboarding data, risk profile, compliance documentation, financial data, and performance indicators.

Part numbers, descriptions, classifications, specifications, SKUs, catalogues, contracted services, SLAs, and pricing schemes.

Procurement history, performance reviews, and supplier benchmarks over time.

Contracted services, service-level agreements (SLAs), pricing structures, and procurement categories.

Purchase orders, invoices, procurement history, payment terms, and delivery schedules.

Legal contracts, terms and conditions, regulatory compliance records, certifications, and audit trails.

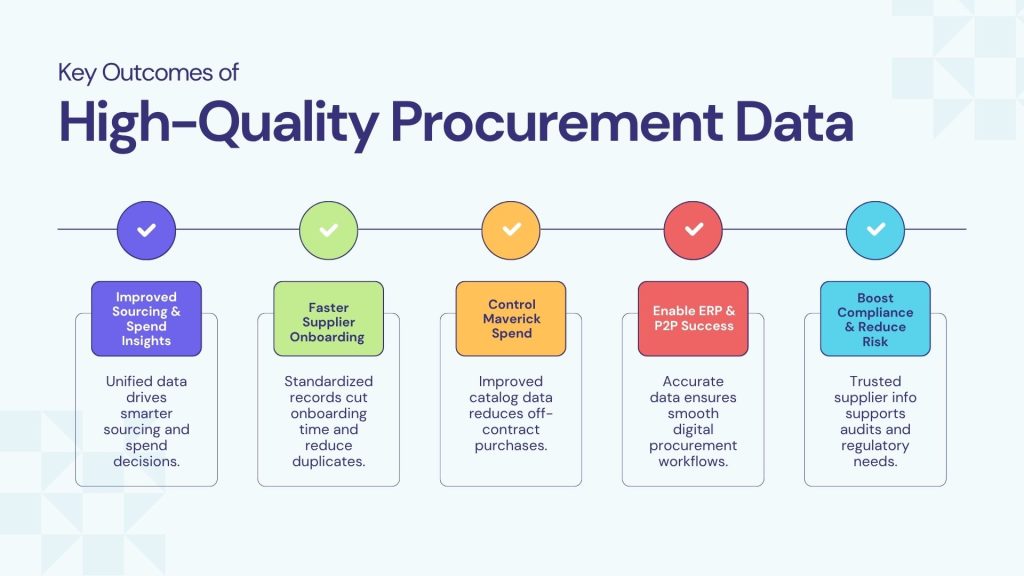

Clean, reliable procurement data is critical to supporting functions such as strategic sourcing, contract management, spend analysis, supplier performance monitoring, and digital procurement automation. It is especially valuable in sectors like manufacturing, oil & gas, energy, and mining, where accurate MRO procurement data can directly impact downtime and production continuity.

Maintaining high-quality procurement data also supports effective compliance and risk management, particularly in regulated industries. It enables procurement and finance teams to confidently engage suppliers, meet internal audit standards, and align procurement operations with broader enterprise goals.

The Business Impact of Procurement Master Data

Procurement master data is more than just supplier names and service codes, it is the foundation of every sourcing decision, contract negotiation, and payment cycle. When this data is poor or inconsistent, the consequences ripple across the organization. But when it is clean, complete, and well-governed, the benefits are measurable and significant.

Business Consequences of Poor Procurement Master Data

Consequence | Impact Area | Example Metrics / Business Impact |

Duplicate vendors | Supplier Management | 15–25% of vendor base is often redundant, inflating risk and administrative load |

Inaccurate material/service descriptions | Purchasing Errors | Up to 12% of POs require rework or returns due to unclear descriptions |

Incorrect pricing or info records | Financial Loss | Overpayments and contract leakage can cost 1–2% of total spend annually |

Missed compliance requirements | Risk & Legal | 100% regulatory audit failure in some industries without tax ID / ESG flags |

Disrupted procurement automation | Operational Efficiency | eProcurement or guided buying tools become ineffective with dirty data |

Sourcing delays | Time-to-Value | Vendor onboarding or sourcing cycles delayed by 10–15% due to incomplete data |

Business Impact of Well-Managed Procurement Master Data

On the flip side, when procurement master data is well-structured and governed, the results are transformative:

Supplier rationalization through data-driven insights can reduce vendor count by 10-15% and unlock volume discounts.

Rationalizing vendors and materials across plants avoids tail-spend leakage and unlocks negotiated pricing.

Aligning vendor and invoice data lowers mismatch rates by 30%, reducing delays in payment processing.

By eliminating duplicate and obsolete items, organizations can significantly cut excess MRO stock, freeing up working capital.

Clean, classified service and material data improves supplier matching, bid creation, and quote comparisons.

Trusted, enriched item/service master data guides users to preferred suppliers and contracts within procurement platforms.

Common Use Cases and Client Successes

Verdantis’ procurement data management solutions empower leading enterprises to streamline sourcing, improve supplier engagement, and control spend with accurate, standardized master data.

Verdantis’ AI-powered tools- AutoEnrich AI, AutoClass AI, AutoTrans AI, and Integrity – help global organizations cleanse, enrich, and govern procurement master data at scale across complex ERP, S2P, and SCM ecosystems.

Performance Metrics & KPIs for Procurement Master Data Success

To ensure long-term value from Procurement Master Data Management initiatives, it’s essential to track the right metrics. These KPIs help measure data quality, procurement efficiency, and ROI from master data efforts:

% of Complete Supplier/Material Master Records

What it measures: How many master records have all required fields populated - including specifications, classification codes, sourcing details, and compliance data.

Target: >95% completeness

Example:

A leading energy utility found that only 62% of their supplier master data had valid tax identifiers and contact details. After enrichment, completeness jumped to 97%, accelerating vendor onboarding and payment cycles.

Duplicate Record Reduction

What it measures:How much duplicate or redundant data has been removed from the supplier or item master.

Target: ≥80% reduction

Example:

A global oil & gas firm eliminated 18,000 duplicate MRO part numbers (30% of total) using AI-powered cleansing. This saved ~$6.5M in inventory carrying costs and improved spend visibility.

Time to Onboard New Vendors

What it measures:Average time (in days) to validate, approve, and activate new supplier records.

Target: <5 business days

Example:

Before implementing master data governance, a chemical company took 12–15 days to onboard suppliers. With workflow automation and validations in place, this dropped to 3 days, reducing delays in urgent sourcing.

Reduction in Maverick Spend

What it measures:The proportion of spend outside of negotiated contracts or approved catalogs.

Target: <5% of total indirect spend

Example:

A heavy manufacturing company saw maverick spend drop from 21% to 6% by ensuring all items and services were cataloged with preferred vendors and accurate pricing in their ERP system.

Procure-to-Pay (P2P) Cycle Time

What it measures: Time taken from requisition creation to invoice payment.

Target: <20 days for indirect purchases

Example:

A packaging company streamlined their P2P process from 42 days to 18 by integrating clean master data into their SAP and Coupa systems. This improved cash flow and strengthened vendor relationships.

Conclusion

Procurement master data is no longer just a back-end necessity, it’s a strategic asset that drives sourcing efficiency, spend control, and digital transformation. By adopting a smart, AI-driven framework for cleansing, standardizing, enriching, and governing procurement data, organizations can eliminate inefficiencies, reduce costs, and accelerate supplier collaboration.

With proven processes and best practices, companies can transform their procurement operations moving from fragmented data silos to a unified, intelligent system that supports better decisions and delivers measurable ROI. Verdantis empowers enterprises to make this shift with automation, domain expertise, and deep integration into existing ERP and procurement ecosystems.

Organizations that embed strong data governance into their procurement strategy gain a competitive edge in cost savings, agility, and compliance.

What People Ask

How can clean procurement data improve sourcing decisions?

Accurate and standardized procurement data provides clear visibility into supplier performance, spend categories, and contract compliance, enabling more strategic sourcing and better negotiations.

What types of procurement data does Verdantis help manage?

Verdantis specializes in cleansing and governing supplier master data, material and service descriptions, purchase info records, and vendor classifications, across multiple business units and systems.

Is AI really effective for procurement data cleansing?

Yes. AI can rapidly identify duplicates, inconsistencies, and gaps across millions of records, improving data quality and reducing the manual effort involved in traditional cleansing.

Why is procurement data governance important?

Governance ensures procurement data remains accurate and consistent over time. With defined rules, workflows, and audit trails, it prevents data decay and supports regulatory compliance.

How does better procurement data reduce maverick or off-contract spending?

When procurement teams have reliable, searchable data on approved suppliers and products, they’re less likely to bypass processes or place unplanned orders, leading to better spend control.

Does Verdantis support integration with existing ERP or sourcing platforms?

Yes. Verdantis tools are ERP-agnostic and integrate with systems like SAP, Oracle, Maximo, and Coupa to ensure procurement data is consistent and synchronized across platforms.

What are the key benefits of using Verdantis for procurement data management?

Faster vendor onboarding, fewer duplicate suppliers, more reliable analytics, cost savings through better visibility, and stronger compliance across global operations.