Introduction

MRO is critical to industrial efficiency, particularly in sectors that rely on complex machinery, such as manufacturing, energy, oil & gas, and utilities. These industries face high stakes when equipment fails—downtime is costly, and delays in finding or ordering the right spare parts can severely impact productivity.

However, the MRO ecosystem still grapples with long-standing challenges:

Outdated or incomplete Bill of Materials (BOM) data

Poor visibility into parts criticality and usage frequency

Fragmented order management systems

Lack of automation in data synchronization and updates

Difficulties in meeting regulatory and compliance requirements

Manufacturing businesses are bound to stick to tight budgets. They like their component lists to be complete, harmonized, updated, and running, always. So, to keep their bill of materials (BOM) regularly refreshed with an updated list of all the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts and quantities of all products, there is a need for essential standardization, normalization, rationalization, attribution, and enrichment. This is where effective master data management comes in.

This article explores how AI-powered solutions, like those offered by Verdantis, are revolutionizing the MRO landscape by automating data enrichment across systems, integrating and maintaining accurate Bills of Materials (BOMs), enhancing visibility into parts traceability and criticality, streamlining work order management, ensuring robust data governance, and empowering intelligent, autonomous decision-making through AI agents..

Transform your MRO Lifecycle into a success story with Verdantis by your side.

What is an Bill of Materials (BOM)?

An Bill of Materials (BOM) is a detailed list of all components, parts, subassemblies, and raw materials required to manufacture, assemble, operate, or maintain a specific piece of equipment. Unlike engineering BOMs, which are focused on product design, BOMs are equipment-focused and are commonly used in asset-intensive industries to manage physical equipment throughout its lifecycle—from procurement to maintenance and eventual replacement.

BOMs play a crucial role in:

Spare parts management

Maintenance planning and execution

Procurement and bill of materials inventory management control

Ensuring operational continuity

Each item in an BOM typically includes information such as part name, part number, description, material type, quantity, and supplier details.

Example: BOM for a Mini Lathe Machine

To better understand the structure and purpose of an BOM, let’s consider the example of a mini lathe machine, as shown in the image below.

The lathe machine consists of numerous parts working together to perform precision machining. Here’s how an BOM for this equipment will contain:

Below is an example of how an BOM can be created using a Mini Lathe Machine (as shown in the image):

Item No. | Component Name | Part No. | Quantity | Material | Remarks |

1 | DC Motor | MTR-DC400 | 1 | Metal | Drives the lathe spindle |

2 | Speed Control Assembly | SPC-CTRL001 | 1 | Composite | Variable speed control |

3 | 3-Jaw Chuck | CHK-3J001 | 1 | Steel | Holds the workpiece |

4 | Headstock | HDS-400 | 1 | Cast Iron | Houses spindle and motor |

5 | Tailstock | TLS-400 | 1 | Cast Iron | Supports long workpieces |

6 | Tailstock Drill Chuck | TLS-DRL001 | 1 | Steel | Holds drill bits |

7 | Crosslide | CRSLD-400 | 1 | Cast Iron | Allows X-axis movement |

8 | Lathe Bed | BED-400 | 1 | Cast Iron | Base structure |

9 | Faceplate | FPLT-001 | 1 | Steel | Workpiece mounting |

10 | Leadscrew Handwheel | LDWH-001 | 1 | Steel | Manual feed control |

11 | Tailstock Feed Handwheel | TFW-001 | 1 | Steel | Tailstock quill movement |

12 | Hex Keys | HEX-SET | 1 set | Steel | For adjustment and assembly |

13 | Tool Post | TPOST-001 | 1 | Steel | Holds cutting tools |

14 | Spindle Bars | SPB-002 | 2 | Steel | For mounting centers/chucks |

15 | Drawbolt and Washer | DRB-001 | 1 set | Steel | For tool or chuck holding |

Each of these parts would be listed in the BOM along with relevant details like quantity, material (steel, cast iron, etc.), and specifications.

Why BOM Management Matters?

Maintaining an accurate BOM is essential for:

Efficient repairs and replacements – Knowing exactly what part is needed minimizes downtime.

Standardizing maintenance procedures – Ensures technicians use the correct parts.

Cost control – Prevents over-ordering or under-stocking of components.

Regulatory compliance – Some industries require documentation of all equipment components.

Process of Creating an BOM

Creating a comprehensive Equipment Bill of Materials (EBOM) is a critical step in ensuring efficient equipment maintenance, asset management, and operational planning. The EBOM outlines the structural and functional makeup of equipment, facilitating accurate procurement, maintenance, and bill of materials inventory management control. The process typically involves the following key steps:

Current Industry Use

- Manufacturing: Ensuring accurate production planning.

- Maintenance & Repair: Facilitating efficient spare part procurement and servicing.

- Regulatory Compliance: Providing detailed documentation for audits and certifications.

What is a Work Order?

A Work Order (WO) is an official request to perform maintenance, repair, or inspection tasks on equipment or machinery. It contains details such as task descriptions, assigned personnel, required materials, and deadlines.

Work Order Process & Industry Applications

Work Order Process

- Initiation: Identifying maintenance needs and creating a WO.

- Approval: Managerial review and resource allocation.

- Execution: Technicians perform tasks as per the WO instructions.

- Closure: Updating records and marking the task as complete.

- Analysis & Reporting: Reviewing performance and identifying areas for improvement.

Industry Applications

- Preventive Maintenance: Scheduling routine servicing to prevent failures.

- Corrective Maintenance: Addressing unexpected equipment breakdowns.

- Regulatory Compliance: Ensuring adherence to safety and operational standards.

Current Industry Scenario

Work Order Process Without AI

Manual BOM Management:

Engineers create and update BOMs manually, leading to human errors and inconsistencies.

BOMs are stored in spreadsheets or legacy systems that lack real-time synchronization with inventory.

Work Order Generation:

Maintenance teams rely on scheduled inspections rather than predictive failure analysis.

Work orders are manually generated based on periodic assessments or reactive maintenance requests.

Many times, engineers forget to create work orders, leading to delays in maintenance and equipment downtime.

Procurement & Bill of Materials Inventory Management Challenges:

Spare parts procurement is often inefficient due to lack of visibility into stock levels.

Delays occur in acquiring the right parts, increasing downtime and maintenance costs.

Execution & Documentation:

Work orders are paper-based, requiring technicians to manually log repairs and replacements.

Data entry errors and loss of records impact future maintenance planning and compliance audits.

High Downtime & Reactive Maintenance: Companies react to equipment failures instead of preventing them, leading to unplanned downtime and increased costs.

Inefficient Resource Allocation: Manual work order assignments cause inefficiencies in technician scheduling and spare parts availability.

Limited Data Insights: Paper-based records make it difficult to analyze failure patterns and optimize maintenance schedules.

Regulatory Compliance Risks: Inconsistent documentation can lead to compliance violations and operational risks.

Modernizing Equipment Management with AI and Automation

The transition from traditional methods to AI-driven processes allows companies to:

- Automate BOM Updates: AI-powered systems ensure real-time synchronization of BOMs with inventory and maintenance records.

- Predict Equipment Failures: Machine learning algorithms detect anomalies and trigger preventive work orders.

- Streamline Work Order Management: Automated scheduling optimizes technician assignments and spare part availability.

- Enhance Compliance & Reporting: Digital workflows eliminate paperwork, improving accuracy and regulatory adherence.

Discover how Verdantis’ AI-powered solutions can optimize data governance, enhance compliance, and drive operational efficiency.

Revolutionizing Equipment Management: AI-Powered Bill of Materials (BOM) Flow

Effective equipment management is crucial for ensuring seamless operations, reducing downtime, and optimizing maintenance schedules. Bill of Materials Management software follows a structured process to manage equipment efficiently, ensuring accuracy and reliability in data handling.

- Equipment Data Collection

- Extract equipment details from ERP, CMMS, and legacy systems.

- Gather equipment hierarchies, technical specifications, and manufacturer details.

- Data Standardization & Cleansing

- Identify inconsistencies in equipment descriptions and metadata.

- Use AI-powered algorithms to normalize and standardize data.

- Remove duplicate or redundant entries.

- BOM Validation & Optimization

- Cross-check BOM structures with manufacturer data.

- Optimize BOMs for accuracy and completeness.

- Assign missing classifications based on industry standards.

- Equipment Criticality Analysis

- Assess criticality based on factors such as failure impact, maintenance costs, and availability of spare parts.

- Use AI models to rank equipment criticality and prioritize maintenance tasks.

- Automated Equipment Documentation Updates

- Integrate manufacturer updates directly into equipment records.

- Maintain an audit trail for all changes to equipment documentation.

- Preventive & Predictive Maintenance Scheduling

- Utilize AI-driven insights to create optimal maintenance schedules.

- Automate work order generation based on equipment health indicators.

- Integrate real-time sensor data to trigger predictive maintenance alerts.

- Approval & Integration into ERP/CMMS

- Validate and approve all updates through a structured workflow.

- BOM management software changes across all relevant systems, ensuring data consistency.

Parts Criticality Management

Parts Criticality Management is the process of categorizing and prioritizing spare parts based on their impact on equipment performance, safety, and overall operations. This ensures that critical components are readily available to minimize downtime and operational disruptions.

Steps in Parts Criticality Management:

- Classification of Parts:

- Critical: Directly impacts operations and safety.

- Essential: Necessary for function but has alternatives.

- Non-Critical: Low impact on operations and can be procured with lead time.

- Risk Assessment:

- Analyzing failure history, lead times, and supplier reliability.

- Determining the financial and operational impact of part unavailability.

- Inventory Optimization:

- Ensuring that critical parts are always stocked.

- Using AI-driven demand forecasting for smarter procurement.

- Supplier and Lead Time Management:

- Establishing reliable vendor relationships.

- Reducing dependency on single suppliers.

- Integration with Maintenance Plans:

- Aligning part availability with predictive maintenance schedules.

- Reducing emergency procurement costs and unexpected downtime.

Importance in the Industry Today:

- Prevents unplanned downtime by ensuring the availability of mission-critical components.

- Reduces excessive inventory costs by avoiding overstocking of non-critical parts.

- Improves maintenance efficiency by aligning spare parts with work order priorities.

- Enhances safety compliance by maintaining stock for regulatory requirements.

Understanding Criticality Models Across Industries

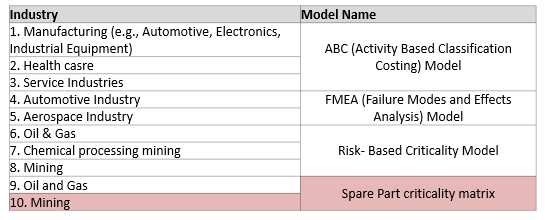

The table highlights the application of specific criticality models in various industries, emphasizing the importance of tailored approaches based on the unique characteristics and risks associated with each sector.

Key Observations:

- Diverse Industry Applications: The table covers a wide range of industries, including manufacturing, healthcare, service, automotive, aerospace, oil & gas, chemical processing, and mining. This demonstrates the broad applicability of criticality assessment in optimizing maintenance and resource allocation.

- Specialized Models: Each industry utilizes specific models designed to address its unique needs and challenges. For example, the FMEA (Failure Modes and Effects Analysis) model is particularly relevant to the automotive and aerospace industries, where safety and reliability are paramount.

- Focus on Risk: Several industries, such as oil & gas, chemical processing, and mining, employ Risk-Based Criticality Models. This highlights the emphasis on identifying and mitigating potential risks in these high-hazard sectors.

- Cost Considerations: The ABC (Activity Based Classification Costing) Model is used in manufacturing to assess the cost implications of downtime and maintenance.

- Spare Part Management: The Spare Part Criticality Matrix is specifically mentioned for the mining industry, indicating the importance of efficient spare parts management in this sector.

- ABC (Activity Based Classification Costing) Model: This model focuses on identifying and classifying activities based on their cost drivers. In the context of maintenance, it helps determine the cost implications of downtime and identify opportunities for cost reduction.

- FMEA (Failure Modes and Effects Analysis) Model: This is a systematic approach to identifying potential failures in a system or process and assessing their impact. It helps prioritize maintenance efforts and develop strategies to mitigate risks.

- Risk-Based Criticality Model: This model assesses the criticality of assets based on the potential risks associated with their failure. It considers factors such as safety, environmental impact, and production loss.

- Spare Part Criticality Matrix: This tool categorizes spare parts based on their criticality, considering factors such as lead time, cost, and impact of unavailability. It helps optimize inventory management and ensure the availability of critical parts.

Significance:

This table underscores the importance of selecting the appropriate criticality model based on the specific industry and its unique challenges. By utilizing these models, organizations can:

- Prioritize Maintenance Efforts: Focus on critical assets and components to minimize downtime and prevent costly failures.

- Optimize Resource Allocation: Allocate maintenance resources effectively based on the criticality of assets.

- Improve Safety and Reliability: Implement proactive measures to mitigate risks and ensure the safe operation of equipment.

- Reduce Costs: Minimize downtime and optimize inventory management to reduce maintenance costs.

Breaking Down the Framework

The diagram systematically breaks down the process of determining material criticality, which is essentially the impact of a part’s unavailability when a failure occurs. Here’s a step-by-step explanation:

- Asset Criticality (Score = 4): This is the starting point, highlighting the general impact of the asset on production, key processes, safety, or environmental hazards. A score of 4 suggests a significant impact.

- Consequence to Asset (Downtime) (Score = 3): This assesses the direct impact on the asset itself in terms of downtime. A score of 3 indicates a notable consequence, likely leading to production disruption.

- Site Consequence (Score = 8): This is where the framework introduces a more nuanced evaluation. It combines the “Consequence to Asset” with a categorization of potential disruptions:

- A – Major Disruption: Complete halt in production, safety hazards, or environmental risks.

- B – Significant Disruption: Reduced production or potential for a complete stop.

- C – Minor Disruption: Availability of alternatives or low safety risk.

- D – Inconvenience: Low downtime and safety risks.

- E – No Impact: Negligible effect on production and minimal risks.

The example shows a “Site Consequence” score of 8, indicating a significant potential disruption.

- Consequence Probability (Score = 3): This considers the likelihood of the failure occurring. A score of 3 suggests a moderate probability.

- AM Strategy (Event Type) (Score = 1): This factor takes into account the existing Asset Management strategy in place. A score of 1 might indicate a reactive or run-to-failure approach.

Calculating Material Criticality

The diagram then presents a formula for calculating the Material Criticality score:

Material Criticality = (Site Consequence + Consequence Probability) × AM Strategy (Event Type)

In the given example:

Material Criticality = (8 + 3) × 1 = 11

This score of 11 represents the overall criticality of the spare part. A higher score signifies a more critical part, demanding greater attention in terms of inventory management and maintenance planning.

Practical Implications

This framework allows organizations to:

- Prioritize Spare Parts: Focus on stocking critical parts to minimize downtime and potential risks.

- Optimize Inventory: Avoid overstocking less critical parts, reducing storage costs.

- Develop Effective Maintenance Strategies: Implement proactive maintenance for critical assets and adopt cost-effective strategies for less critical ones.

- Improve Safety and Environmental Compliance: Ensure the availability of parts that mitigate safety and environmental hazards.

Expanding the Explanation with a Real-World Example

To illustrate the practical application of the criticality assessment framework, consider the example provided for a CNC Milling Machine. This example demonstrates how the principles of criticality assessment can be applied to a specific asset within a manufacturing setting.

Example: CNC Milling Machine Criticality Assessment

The example utilizes a scoring system where each factor is rated on a scale of 1 to 5, with 1 being low impact and 5 being high impact. The factors considered are:

- Safety & Compliance (25% Weight, Rating 4): This indicates a significant safety and compliance impact if the machine fails.

- Production Impact (25% Weight, Rating 5): A high rating suggests that the machine is crucial for production, and its failure would severely disrupt operations.

- Downtime Cost (20% Weight, Rating 4): This reflects the substantial financial loss associated with machine downtime.

- Redundancy (15% Weight, Rating 2): A low rating implies limited redundancy, meaning there are few or no backup machines.

- Maintenance History (10% Weight, Rating 3): This suggests a moderate history of maintenance issues.

- Age & Condition (5% Weight, Rating 3): This indicates the machine is neither brand new nor extremely old, but its condition warrants attention.

Calculating the Weighted Score

Each factor’s rating is multiplied by its weight to determine the weighted score. For example, Safety & Compliance has a weighted score of 1 (4 x 0.25). The sum of these weighted scores gives the Total Score, which in this case is 3.8 / 5.0.

Interpreting the Score

The interpretation of the score is as follows:

- Score 4.0 – 5.0 → Critical Asset: Requires high-priority monitoring and maintenance.

- Score 3.0 – 3.9 → Moderate Criticality: Needs proactive maintenance, but the impact is manageable.

- Score 1.0 – 2.9 → Low Criticality: Minimal impact, standard maintenance practices apply.

In our CNC Milling Machine example, the score of 3.8 falls within the Moderate Criticality range. This means that while the machine doesn’t require the same level of urgency as a critical asset, it still necessitates proactive maintenance strategies to prevent potential disruptions and minimize downtime costs.

Connecting to the Parts/Spares Criticality Framework

This example directly relates to the Parts/Spares Criticality framework. The “Site Consequence” in the framework, which considers the impact of a part’s unavailability, aligns with the “Production Impact” and “Downtime Cost” factors in the CNC Milling Machine example. Similarly, “Consequence Probability” can be inferred from the “Maintenance History” and “Age & Condition” factors.

Practical Application and Benefits

By applying this scoring system to the CNC Milling Machine, the organization can:

- Prioritize Maintenance Efforts: Focus on proactive maintenance to prevent failures and minimize downtime.

- Optimize Spare Parts Inventory: Stock critical spare parts based on the machine’s criticality score.

- Allocate Resources Effectively: Allocate maintenance resources based on the criticality of different machines.

- Improve Overall Equipment Effectiveness (OEE): Reduce downtime and improve production efficiency.

Equipment Management Process: A Step-by-Step Breakdown

- Load Equipment Information: Gather and input equipment data from various sources (drawings, manuals, etc.).

- Extract Equipment BOM Information: Use AI to extract the Bill of Materials (BOM) data from the loaded information.

- Material List Extraction from BOM: Create a structured material list from the extracted BOM data.

- Gather Initial Material Details of the BOM Material List: Extract and organize essential material details (BOM ID, manufacturer, supplier, descriptions) into a spreadsheet format.

- Create Low-Level Codes: Generate low-level codes to categorize and organize materials.

- Identify Critical Stock Materials: Analyze the material list to determine which materials are essential for operations and should be kept in stock.

- Criticality Assessment: Perform a criticality assessment to understand the impact of stockouts on operations.

- Extract Criticality Determination Attributes: Extract attributes (like item category) that are crucial for the criticality matrix.

- Material Master Inventory Check: Compare the material list against the master inventory to check stock levels.

- Inventory Check and Detailed Output Generation: Conduct a detailed inventory check and generate a comprehensive output report.

- Create Components for New Materials: If new materials are identified, create their components in the system.

- Compare BOM Item Details with Maintenance Work Orders: Compare BOM item details with maintenance work orders to identify discrepancies.

- Link Newly Created Items to BOM: Link any newly created items to the Equipment BOM (EBOM) for a complete record.

Use Cases and Current Challenges in the MRO Industry

The Engineering Bill of Materials (E-BOM) is a comprehensive document detailing all materials, components, and sub-assemblies required for product manufacturing. Master Data Management (MDM) focuses on managing an organization’s critical data, including core business entities like products, customers, and suppliers. Advanced materials catalog management services complement MDM, offering specialized tools for material master catalog cleansing and efficient Master Data Cataloging solutions.

In the case of E-BOMs, as it usually reflects the products designed by engineering, it is not related to any form of modular BOMs or configurable BOMs. Also called the ‘as designed’ amongst many manufacturers, they are produced in engineering and are typically driven from CAD tool, which ultimately drives its focus around final assemblies list of parts or components. E-BOMs mainly align to sales BOMs and service BOMs. Since this BOM includes complex large numbers like substitute and alternate part numbers along with parts that are contained in drawing notes, there is a growing need amongst the data owners and data stewards for proper de-duplication, streamlining and refining of data and its contents. This can be done only by taking appropriate data quality improvement and governance measures.

MDM for E-BOM equipment is one of the best ways to reduce costs and standardize procurement processes. It helps recognize duplicate components, and thus, allows adequate cost-cutting. A recent implementation by Verdantis saw inventory reduction of 5-6%. That can be a huge figure in a company with over $15 billion in annual revenues.

An advantage gained through MDM efforts is the identification of a fixed format for the creation of the E-BOM. The MDM tools used, will help distinguish between the assets that require an E-BOM, and help decide what items must feature on the E-BOM, along with what data must feature on the E-BOM.

Business benefits can be seen in the form of improved procurement and MRO processes resulting in managing and reducing costs, when firms implement master data management solutions for their E-BOMs.

MDM ensures master data consistency, and materials catalog management services focus on cleansing material master catalogs, collectively ensuring accuracy throughout the E-BOM. This synergy minimizes errors, reducing production delays and rework.

This was recently seen when a large agricultural nutrient provider having over 50 manufacturing facilities across North America leveraged Verdantis’ Artificial Intelligence-based solutions to remarkable effect, for harmonizing BOM data, Purchase order data and Item master data.

Problem Statement

Organizations struggle with incorrect or outdated BOM, Equipment, and material data in their Enterprise Resource Planning (ERP), Computerized Maintenance Management Systems (CMMS), or other siloed systems. This issue stems from:

- Improper updates in work orders

- Disconnected silos managing MRO activities

- Lack of a centralized information management system

AI-Powered Solution

BOM Software tackles this issue by implementing a structured, AI-powered approach:

- System Assessment: Identify client systems (ERP, CMMS, independent silos) and analyze how BOM, work orders, and equipment details are structured.

- Data Mapping & Migration: Align information across systems, create a unified field structure in BOM Software, and migrate legacy data.

- Work Order History & Classification: AI-driven parsing and classification of work orders into preventive, scheduled, or ad hoc maintenance.

- Data Gap Analysis: Identify missing or inconsistent data based on historical trends and generate update reports.

- Approval & Finalization: Submit updates for approval and integrate changes into client systems.

Problem Statement

Organizations still manually update 2D/3D equipment drawings and BOMs, leading to inefficiencies and errors. While OEMs (Original Equipment Manufacturers) increasingly provide direct updates, companies lack automated systems to extract, validate, and integrate this information.

AI-Powered Solution

Bill of Materials Management Software enables seamless integration and update of equipment drawings and BOMs:

- Centralized Repository: Establish a structured repository for equipment drawings, specifications, BOM data, and materials.

- Data Extraction: Implement API/FTP mechanisms to retrieve updated drawings from SAP, client systems, or OEM databases.

- AI-Based Information Extraction:

- 2D Drawings: AI-driven parsing to extract relevant BOM details.

- 3D Drawings: Integration with CAD software for automated analysis.

- Data Population & Version Control: AI populates BOM and equipment specifications while maintaining version tracking.

- Approval & System Integration: Submits changes for approval before updating the ERP system.

Interpreting regulatory requirements and creating preventive maintenance schedules is a significant challenge, especially for US-based clients who must comply with strict industry regulations.

AI-Powered Solution

BOM Management Software automates compliance tracking and maintenance scheduling through:

- Document Management System (DMS): A central repository to store manuals, maintenance catalogs, and regulatory documents with version control.

- AI-Driven Document Parsing: Extraction of maintenance requirements from manuals and mapping them to relevant assets.

- Automated Preventive Maintenance Orders: AI analyzes compliance requirements to create optimized maintenance schedules.

- Approval Workflow Implementation: Ensures structured review and validation of generated maintenance plans.

Problem Statement

Organizations focus on asset/equipment criticality but often overlook spare part criticality, leading to inefficiencies in procurement and maintenance planning.

AI-Powered Solution

BOM Software provides a structured approach to spare part criticality assessment:

- Data Collection: Extract spare parts, BOM, and equipment data from ERP systems.

- Parameter Analysis: Evaluate spare part criticality based on:

- Failure impact

- Probability of failure

- Procurement difficulty

- AI-Based Criticality Scoring: Implement machine learning models to calculate criticality scores based on industry-specific best practices.

- Comparison & Reporting: Highlight differences between new and existing criticality scores for validation.

- Cumulative Asset Risk Assessment: Provide a holistic view of asset criticality across sites, enabling informed decision-making.

Problem Statement

Many organizations struggle with standardizing materials and implementing correct taxonomy frameworks such as KKS codes for asset location or ANSI numbering for asset identification.

AI-Powered Solution

BOM tool streamlines taxonomy standardization by:

- Data Classification: AI-powered categorization of materials and assets.

- Taxonomy Mapping: Alignment of client data with global industry standards.

- Automated Validation: AI-based checks for taxonomy inconsistencies.

- Update & Approval Workflow: Ensuring compliance with international classification standards before integration into client systems.

Conclusion

The MRO industry is undergoing a digital transformation, and AI-driven synchronization is at the forefront of this change. By addressing challenges such as outdated BOM data, manual updates, regulatory complexities, spare part criticality assessment, and taxonomy standardization, BOM management software enhances operational efficiency, reduces errors, and ensures seamless integration of critical data across systems. As industries continue to evolve, AI-powered solutions will become essential in optimizing maintenance strategies and improving asset management.

Incorporating Master Data Management and advanced materials catalog management services providers like Verdantis into E-BOM management is a strategic approach for organizations aiming to thrive in the digital age. Material master catalog cleansing empowers businesses to navigate manufacturing complexities with agility and confidence. As industries evolve, the collaborative synergy of E-BOM, MDM, and materials catalog management services will continue to drive innovation, enabling organizations to excel in today’s dynamic manufacturing landscape.